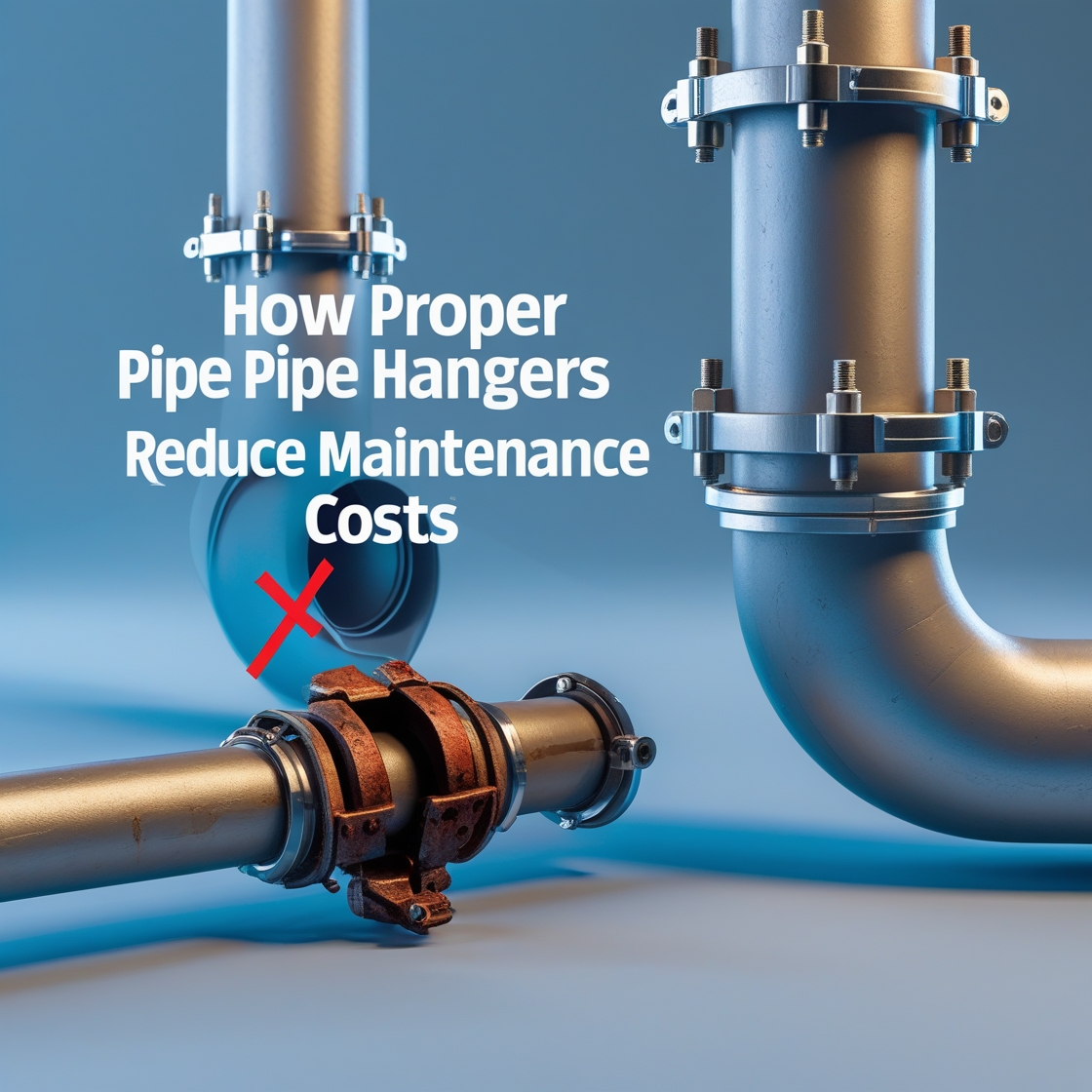

Maintenance is a significant concern for industries and commercial buildings that rely heavily on extensive piping systems. Pipe hangers play an essential role in reducing maintenance costs by preventing premature wear and tear. A well-designed pipe hanger system helps in controlling movement due to thermal expansion, vibration, and mechanical stress, ensuring that pipes do not experience undue strain. Poorly installed or low-quality hangers can lead to frequent breakdowns, requiring constant repairs and increasing operational costs. By using high-quality pipe hangers, companies can significantly extend the lifespan of their piping infrastructure. Regular maintenance checks, combined with durable hanger systems, help in detecting minor issues before they escalate into major problems. Moreover, corrosion-resistant materials, such as stainless steel or galvanized coatings, can further enhance the durability of pipe hangers, reducing the need for frequent replacements. Businesses that prioritize quality pipe hangers ultimately save on labor, repair costs, and system downtime, making it a worthwhile investment in the long run.

How Proper Pipe Hangers Reduce Maintenance Costs

About author

Related posts

Pipes are a fundamental component in any construction project, whether in residential, commercial, or industrial buildings. However, the durability and... Continue reading

Vibration in piping systems is a common yet often overlooked issue that can lead to significant damage over time. Excessive... Continue reading

With years of experience and a commitment to excellence, Surefix has established itself as a trusted name in the pipe... Continue reading

Discover the world of Bonnel spring mattresses in this comprehensive beginner's guide. Explore the construction, benefits, and uses of this... Continue reading

Discover everything you need to know about rebonded foam in this beginner's guide. Learn about its properties, benefits, and uses,... Continue reading

Leave a reply